Unlocking the Power of Water Injection: Overcoming Challenges for Ultimate Performance

Unlocking the Power of Water Injection: Overcoming Challenges for Ultimate Performance

Have you ever considered the remarkable benefits of water injection for your vehicle's engine? The performance benefits are a game-changer if implemented correctly. But like any upgrade, it comes with its own set of challenges. In this comprehensive guide, we'll explore the potential roadblocks you might encounter when implementing a water injection system and the solutions to overcome them. Plus, we'll show you why opting for the Aquamist water injection system can mitigate most of the risks involved with implementing water injection.

- System Installation Complexity

Challenge: Installing a water injection system may require technical expertise, and the complexity can vary depending on the vehicle model and the chosen system. Some vehicles have more accessible engine bays and existing infrastructure for easy installation, while others may require custom modifications and intricate routing of components. It's essential to have a clear understanding of the vehicle's engine and the water injection system's requirements to ensure a successful installation.

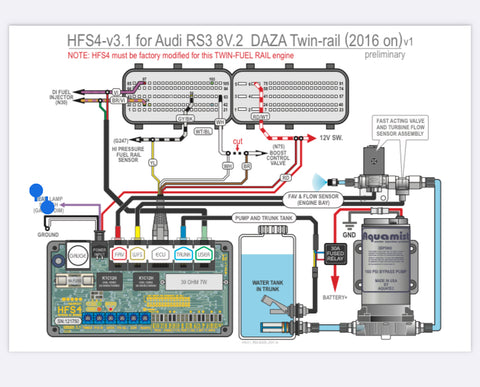

Solution: Seek professional help or follow detailed installation guides tailored to your vehicle. Opt for user-friendly systems like Aquamist, designed for ease of installation, with vehicle specific wiring diagrams available upon request.

- Compatibility

Challenge: Ensuring compatibility between your chosen water injection system and your engine can be a puzzle.

Solution: Start by researching water injection systems compatible with your vehicle's make and model. Manufacturers often provide compatibility lists or guidelines. Aquamist offers a range of systems compatible with various vehicle makes and models, reducing compatibility concerns. Leverage Aquamist's extensive expertise in system integration.

- Component Quality

Challenge: Subpar components can lead to leaks and system malfunctions. It's essential to invest in high-quality components such as pumps, nozzles, lines, and tanks to ensure the system operates reliably. Cutting corners on component quality may result in costly repairs and potential engine or vehicle damage.

Solution: Invest in top-tier components from reputable manufacturers. Quality components are less prone to leaks and failures, contributing to system reliability. Read product reviews and seek recommendations from experienced users to identify top-quality options. Aquamist prides itself on high-quality, reliable components.

- Tuning Challenges

Challenge: Properly tuning a water injection system can be tricky, and incorrect tuning can lead to engine damage or poor performance. Achieving the right balance of water and methanol injection to maximize power while preventing knock requires expertise in engine tuning.

Solution: Rely on professional tuners experienced with water injection setups. They can fine-tune the system to optimize performance and ensure safe operation. Utilize advanced tuning tools and software to monitor engine parameters and make precise adjustments. Aquamist's advanced systems provide precise control, a must for tuners looking for optimized water injection tuning.

- Maintenance

Challenge: Neglecting maintenance can lead to system failures. Maintenance tasks may include checking for leaks, cleaning nozzles, refilling the water/methanol tank, and inspecting system components for wear and tear.

Solution: Create a regular maintenance schedule, and ensure you have spare parts and tools on hand. Aquamist systems are designed for minimal, and where required, easy maintenance. Utilising only distilled or demineralised water in the system, will extent the required maintenance intervals.

- System Failsafes

Challenge: While modern systems often include failsafes, ensuring they are correctly set up and functioning is crucial to prevent engine damage in case of system faults or water supply issues. Failsafes should be tested periodically to verify their reliability and effectiveness.

Solution: Periodically test and verify the functionality of failsafes to ensure they provide adequate protection. Follow the manufacturer's instructions for setting up and testing failsafe mechanisms. Familiarise yourself with the system's warning signals and indicators so that you can respond promptly to any issues. Keep a backup failsafe plan in place in case of unexpected failures. Trust Aquamist's flow sensing based failsafe mechanisms, and other comprehensive failsafe strategies, designed for reliable and robust engine protection. Follow the guidelines for setup and testing.

- Tank Size and Range

Challenge: The tank's capacity determines how long the system can operate before needing a refill. Insufficient capacity may require frequent refilling, which can be inconvenient, especially during long drives or track sessions. Choosing an appropriate tank size based on usage patterns is essential to ensure a seamless experience.

Solution: Opt for a larger tank capacity if you require an extended operating range between refills. Ensure the tank's design allows for easy installation and secure mounting. Choose Aquamist's systems with options for larger tank capacities, with the choice of a 5 litre or 10 litre tank.

Why Choose Aquamist?

While water injection systems vary, Aquamist stands out as a top choice to address these challenges effectively. With a commitment to quality, compatibility, and user-friendliness, Aquamist systems offer a reliable solution to enhance engine performance. Their comprehensive failsafes, easy maintenance, and expert guidance make them an ideal choice for both novice and experienced users.

So, if you're looking to maximize your engine's potential while mitigating challenges, consider Aquamist's water injection systems. They're not just about performance; they're about performance without compromise. Explore the Aquamist advantage and drive with confidence, knowing your engine is protected and optimized for ultimate power.

Leave a comment

Comments will be approved before showing up.

Also in Blog

Mazda Series 5 RX7 meets Aquamist HFS3

Enhancing Engine Longevity: Water Injection’s Protective Role