Unleash Your Engine's Potential: How Water Injection Reduces Engine Knock

Title: Unleash Your Engine's Potential: How Water Injection Reduces Engine Knock

Today, we're delving into a critical aspect of high-performance spark ignition internal combustion engines – the role of water injection in reducing engine knock. Whether you're a seasoned enthusiast or new to the world of automotive performance, understanding this concept is crucial for unlocking your engine's full potential.

The Engine Knock Conundrum

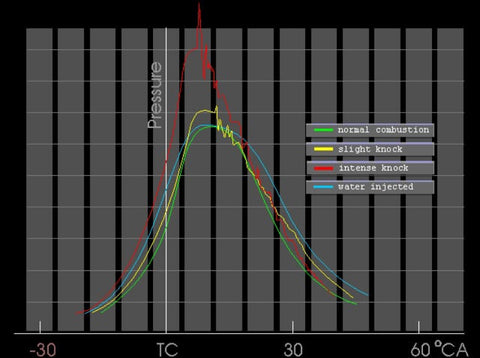

Engine knock, often referred to as detonation, is a common issue in high-performance engines. It occurs when the air-fuel mixture in the combustion chamber ignites prematurely, causing a sharp increase in cylinder pressures. Engine knock not only hampers performance but can also lead to severe engine damage if left unaddressed.

Why Does Engine Knock Happen?

Several factors contribute to engine knock, including:

- High Compression Ratios: High-performance engines often have elevated compression ratios, which can increase the likelihood of knock. When the compression ratio is high, the air-fuel mixture is compressed to a greater extent before ignition. This increased compression generates higher temperatures and pressures in the combustion chamber. In some cases, the air-fuel mixture can spontaneously ignite due to these elevated pressures and temperatures before the spark plug fires, leading to engine knock.

- Advanced Ignition Timing: Advancing ignition timing for improved performance can push the engine to the brink of knock. When ignition timing is advanced too much, the air-fuel mixture may ignite too early in the compression stroke. This premature ignition causes a shockwave that collides with the rising piston, resulting in the characteristic knocking sound. Advanced ignition timing can push the engine to the brink of knock, especially in high-performance setups where the tolerances for safe timing are narrower.

- Increased Boost Pressure and Temperature: Turbocharged and supercharged engines generate higher cylinder pressures and temperatures, making them more susceptible to knock. This combination of increased pressure and temperature, when not properly managed, can cause the air-fuel mixture to ignite prematurely. Controlling this is crucial for preventing knock and ensuring engine durability in these setups.

- Low-Octane Fuel: Low-octane fuel is more prone to spontaneous ignition under high compression and advanced timing conditions. When the fuel-air mixture ignites prematurely, it can lead to engine knock. To prevent this, it's essential to use the appropriate octane-rated fuel recommended for your high-performance engine, as specified by the manufacturer or tuner.

The Solution: Water Injection

Water injection is a powerful and proven solution to mitigate engine knock. Here's how it works:

- Cooling Effect: Injecting a fine mist of water into the intake air charge cools down the combustion chamber. Cooler temperatures reduce the likelihood of spontaneous ignition, effectively countering knock.

- Increased Octane: Water injection effectively raises the octane rating of the fuel-air mixture, allowing for more aggressive ignition timing without knock.

- Carbon Deposit Prevention: Water injection helps prevent carbon deposits on the pistons and cylinder walls, further reducing the risk of knock.

Real-World Success with Aquamist

Aquamist, a UK-based company with over two decades of experience, has been at the forefront of water injection technology. Their universal systems have been successfully applied in a wide range of high-performance engines, including turbocharged and supercharged setups. Check out the Cool Runnings Engineering blog for more Aquamist Water Injection success stories.

https://www.coolrunningsengineering.com.au/blogs/blog

Leave a comment

Comments will be approved before showing up.

Also in Blog

Mazda Series 5 RX7 meets Aquamist HFS3

Enhancing Engine Longevity: Water Injection’s Protective Role